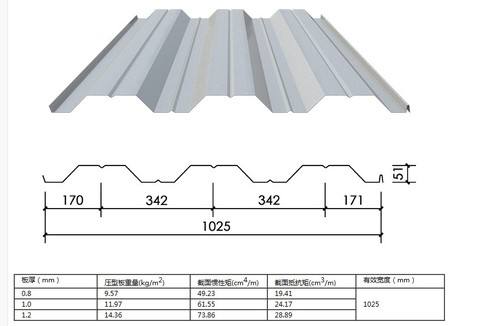

1025 floor decking sheet profiling equipment

The products produced by the 1025 floor decking sheet profiling equipment have the characteristics of light weight, high strength, large load-bearing capacity, and good seismic resistance. They are widely used in the field of multi-story and high-rise steel structure buildings. The products are widely used in power plants, power equipment companies, car showrooms, steel structure factories, cement warehouses, steel structure offices, airport terminals, railway stations, stadiums, concert halls, grand theaters, large supermarkets, logistics centers, Olympic stadiums and other steel structure buildings.

The 1025 floor decking sheet profiling equipment meets the requirements of rapid construction of the main steel structure and can provide a stable working platform in a short time. Moreover, profiled steel sheets can be laid on multiple floors, and the flow construction of layered pouring of concrete slabs can be adopted. In the use stage, the floor decking sheet serves as the tensile reinforcement of the concrete floor slab, which effectively improves the stiffness of the floor slab and saves the consumption of steel bars and concrete.

Here are the technical parameters of this equipment:

- Material feeding method: Passive feeding with manual tensioning.

- Load-bearing capacity of the material feeding rack: 8 tons.

- Frame: Welded with 400H steel.

- Forming machine guide feed frame form: Lateral slide plate type.

- Forming machine form: Wall plate chain drive, and the wall plate thickness is 20 millimeters.

- Shaft diameter: 90 millimeters.

- Chain: 2-inch chain.

- Motor power of the forming machine: 2 sets of 11 kilowatt reducers.

- Linear speed of the forming machine: 8 – 10 meters/minute.

- Number of passes of the forming machine: 22 passes.

- Roll material: High-quality steel is quenched and then hard chrome plated on the surface.

- Motor of the hydraulic station: 4 kilowatts.

- Oil pump of the hydraulic station: Gear pump.

- Cutting method: Hydraulic shearing.

- Material of the forming shear blade: Cr12.

- Heat treatment of the shear blade: The hardness reaches HRC58° – 60°.

- Rolling thickness: 0.8 – 2.0 millimeters.

- Unrolled width of the material: 1250 millimeters.

- Length sizing accuracy: ±2 millimeters.

- Computer control system: Adopting Delta PLC control.